The commentary article on Science originated in October 2019. Prof. Li read a research report in Science by the team of Ferdi Schüth, director of the Max Planck Institute for Coal Research, Vice Chairman of the German Natural Science Research Foundation, and well-known scientist in the field of catalysis and materials research. It reported that his team successfully synthesized corundum nanoparticles with a specific surface area of ~140 m2/g and an average particle size of 13 nm, and claimed that no one had prepared corundum nanoparticles with a specific surface area higher than 100 m2/g. The consensus in the field of nano-ceramic particles is that the larger the specific surface area and the smaller the particle size, the better the catalytic performance and the better the performance of the ceramics obtained by densification.

However, Prof. Li’s team has developed a series of methods and synthesized corundum nanoparticles with sizes of less than 5 nanometers and specific surface areas of 161 m2/g to 253 m2/g from 2015 to 2018. Prof. Li hesitated for two months and finally made up his mind to hold a responsible attitude towards science and commented Schüth’s work. On May 29, 2020, the commentary article was published in Science, reporting that the team has developed three highly efficient preparation methods. The specific surface areas of the prepared corundum nanoparticles are higher than 100 m2/g, also higher than that reported by the Schüth team (140 m2/g). This article also pointed out that Schüth's material is aggregates of 30-200 nanometers, rather than nanoparticles of 13 nanometers, and analyzed the reasons for the large aggregates but the high specific surface area.

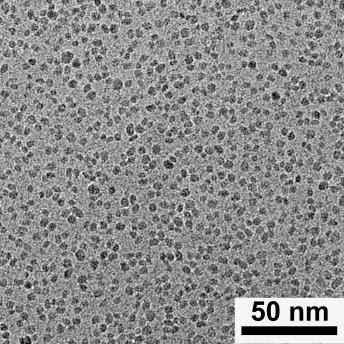

Disperse fine corundum nanoparticles with a narrow size distribution. Shown is a TEM image of corundum nanoparticles with an average size of 3.3 nm and a size distribution of 2 to 6 nm.

From the hard aggregates of corundum with a size of several hundred nanometers in 1998 to the disperse ultrafine equiaxed corundum nanoparticles with narrow size distribution and below 10 nanomaters in 2017, this progress took nearly 20 years. Prof Li’s team reaches the highest top for obtaining supreme fine corundum nanoparticles in the world.

The team then used dispersed, ultrafine, narrow size distribution, equiaxed corundum nanoparticles as raw materials, and sintered alumina ceramics with a density of 99.5% and an average grain size of 30 nm. Its toughness is 60% higher than that of conventional polycrystalline alumina, which is close to tempered glass. At present, the team is using ultrafine corundum nanoparticles as raw materials, cooperating with domestic and foreign research groups, through ultra-high pressure hot pressing technology, aiming to fine-grained alumina nanocrystalline ceramics with a density of more than 99% and an average grain size of less than 15 nanometers .

The successful preparation of corundum nanoparticles shows that thermodynamically unstable nanoparticle materials can be prepared, which provides the possibility for future applications in the fields of catalysis, medicine, composite materials, abrasives, etc. and also lays the foundation for the development of tough alumina nanocrystalline ceramics. In the future, the nano-ceramic water cup in your hand will probably not break when it drops on the ground. If you apply nano-corundum nanoparticles to the surface of the lathe's highly wear-resistant tool, “cutting iron like mud" will become a reality.

Professor Herbert Gleiter with Jiangong Li 's team in 2010

Paper link: https://science.sciencemag.org/content/368/6494/eabb0142.full